Key features

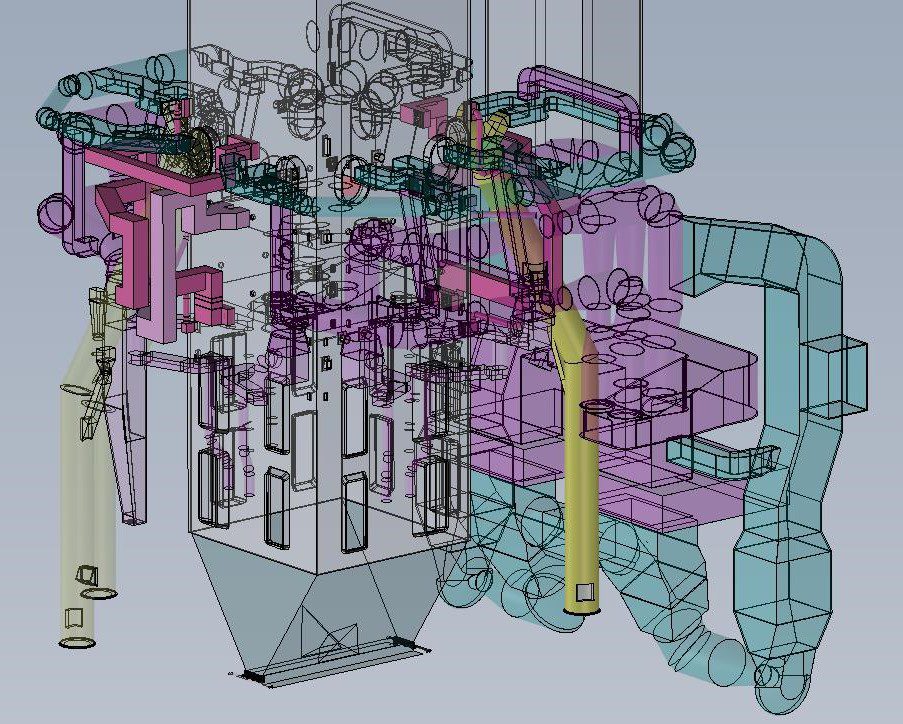

Over Fire Air Systems create combustion staging in the furnace which facilitates low NOx performance. The location of the OFA ports, the volumes, velocity, direction and temperature of the over fire air all have an impact on performance. RJM uses CFD modelling and physical modelling to calculate optimal OFA settings.

Outstanding performance

- Ultra-low NOx emissions firing requires combustion staging

- Incudes Overfire Air (OFA), Boosted Overfire Air (BOFA) and Curtain Air

- RJM’s own design for staged air nozzles

- New RJM ductwork using laser surveys to avoid clashes

- Extensive portfolio of successful installations

- Accurate CFD modelling to ensure optimal performance

- Delivers a low NOx solution that cannot be achieved by burners alone

- Reduces the need for costly post-combustion SCR or SNCR systems

- Designed to work in harmony with firing system

- With BOFA (Boosted Overfire Air) can reduce NOx by up to 40%

Plant applications

- AES Kilroot. As part of the overall NOx reduction project, the OFA ports were replaced to enable higher velocity of injection and multiple angles of injection to control burnout

- Rugeley Power Station. OFA modifications and a new curtain air system were installed as part of the overall deNOx project