Products

RJM offers a wide range of products to suit applications across all types of thermal plant, from ultra-low NOx burners for coal-fired utility boilers to new fuel trains for biomass and EfW plants.

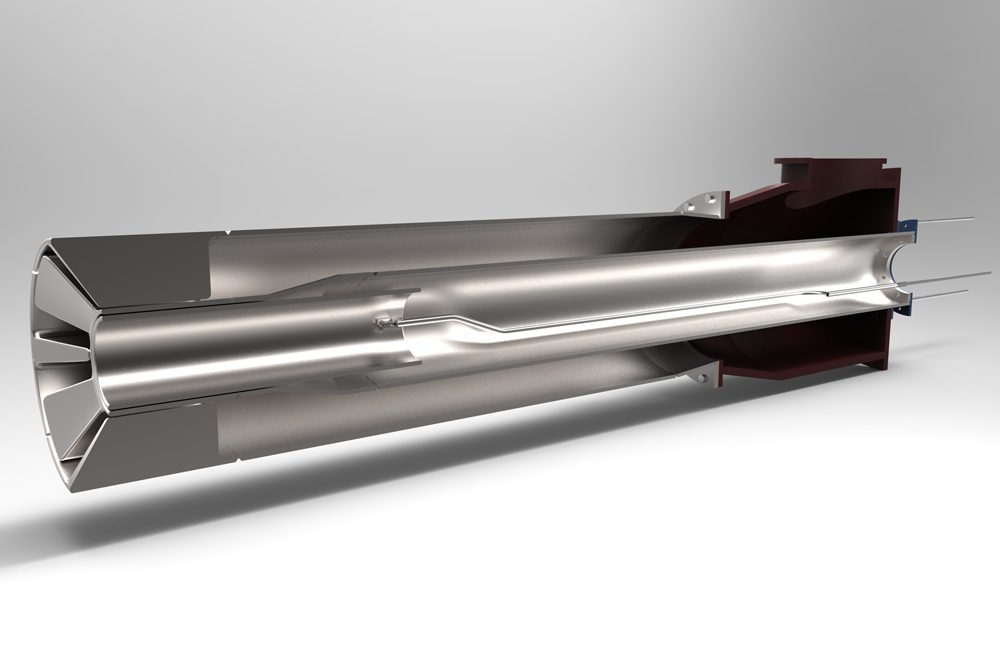

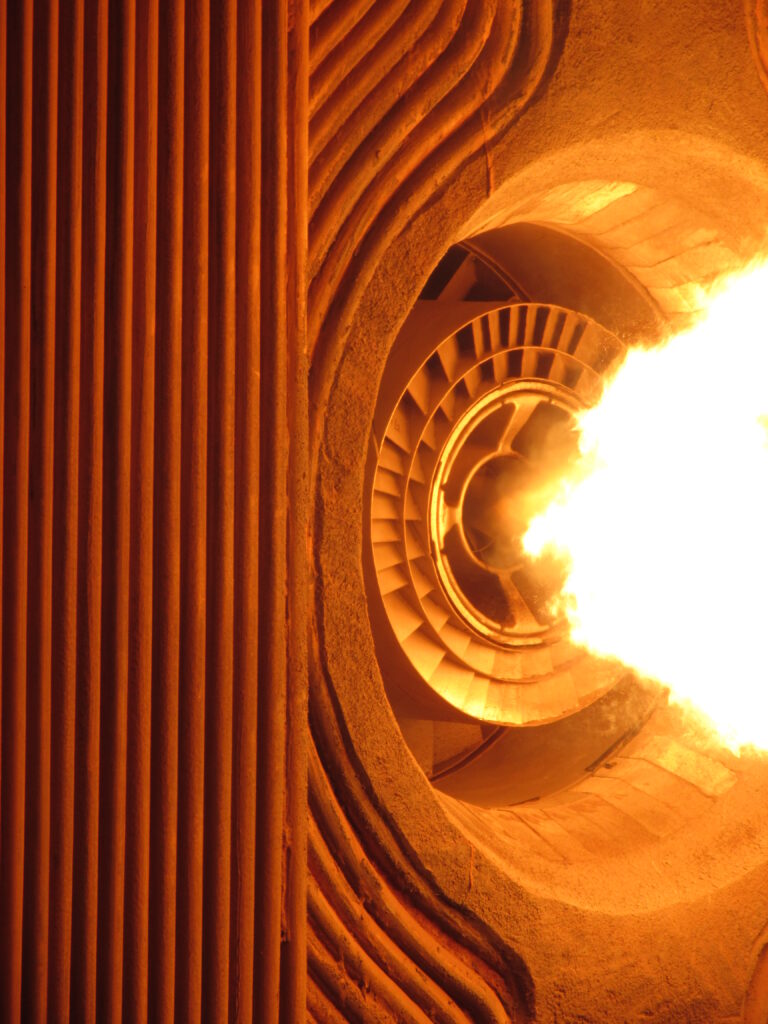

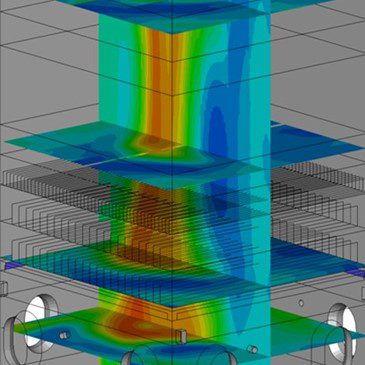

Ultra-low NOx Coal Burners

RJM has been developing its own ultra-low NOx burner technology since the company was founded in 1977.

Ultra-low NOx Gas Burners

With applications to suit a range of different outputs and every firing configuration, RJM has a proven burner solution that can minimise or obviate the needs for secondary NOx reduction measures.

Ultra-low NOx Industrial Gas Burners

RJM has responded to growing demand for ultra-low emission burners by developing a new type of gas burner that can be sized to suit many different industrial applications.

IMPULSE® Cleaning System

The IMPULSE® boiler cleaning system is a development of the pulse detonation propulsion technology pioneered by GE and uses a supersonic shock wave to dislodge material that has built up on surfaces within the boiler.

Multi-Fuel Burners

To control fuel costs and to provide a layer of protection from security of supply issues, RJM has developed a multi-fuel burner that can fire coal, gas or oil.

Ultra-low NOx Oil Burners

RJM has been developing its own ultra-low NOx oil burner technology for over 30 years.

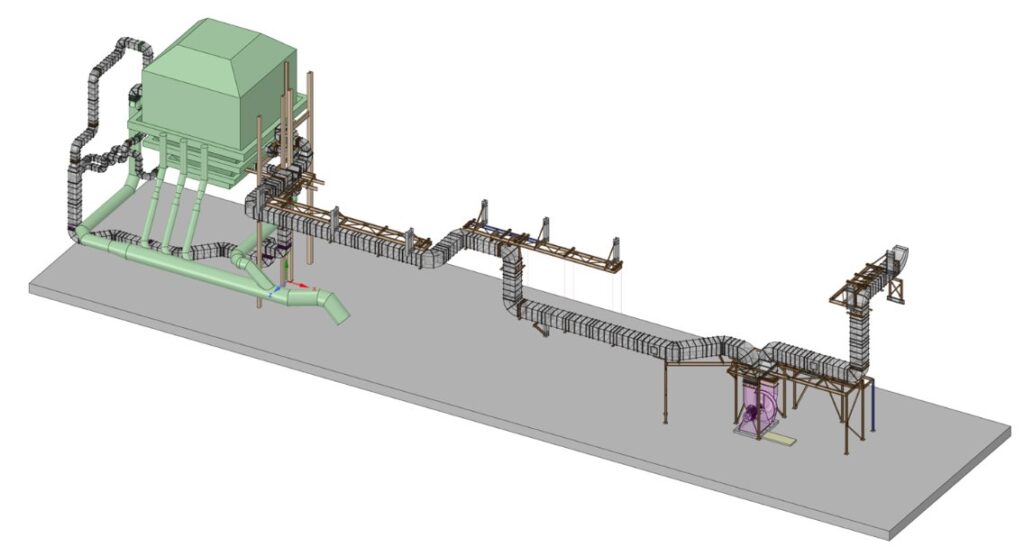

Flue Gas Recirculation Systems

RJM uses FGR or induced FGR (iFGR) systems to take hot flue gases from the existing GR fan outlet and introduce them into the existing FD fan inlet.

Separated Under Fire Air Systems

RJM has developed its own, patented solution to deliver additional air into the centre of the fireball from below.

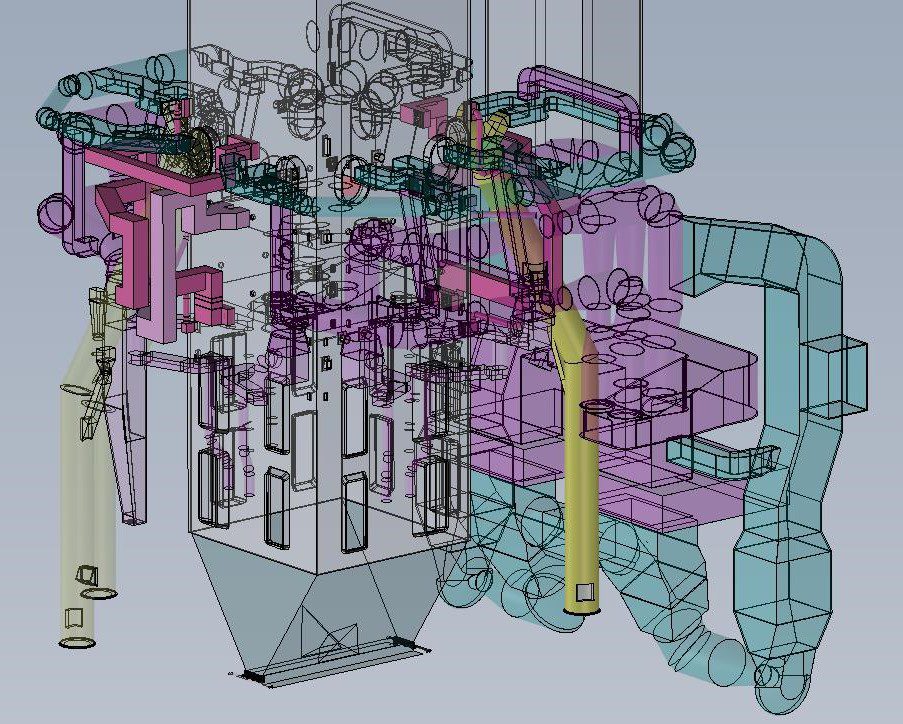

Coal-to-Biomass Conversions

RJM has developed an end-to-end offer that considers every aspects of a plant’s operations.

Biomass & Energy from Waste Firing Systems

RJM’s capabilities across biomass and WtE firing systems are delivering significant improvements.

RDF and SRF Conversions

Faced with changing green subsidies, carbon taxes and security of supply issues, plant operators are increasingly widening their fuel diets to maintain profitable generation.

Fuel Delivery Systems & Modifications

RJM is currently working with a number of biomass and W2E sites in the UK, enabling them to optimise all aspects of their fuel delivery systems.

Burner Management & Combustion Control Systems

RJM works with its customers to ensure burner management and combustion control systems are fully optimised and conducts remote monitoring through the DCS to deliver incremental improvements without the need for outages.

Over Fire Air Systems & Curtain Air Systems

Over Fire Air Systems create combustion staging in the furnace which facilitates low NOx performance.

SNCR Systems

Combined with RJM’s primary NOx reduction systems, IED compliance is now achievable with SNCR, offering significant savings over conventional SCR systems.

RJM Spares & 24.7 Product Support

RJM designs, specifies and oversees the production of a wide range of sophisticated components which are installed at customer sites to deliver specific performance improvements across materials handling, combustion and emissions.

Safety

RJM adheres to all national and international safety legislation and leads on improving safety standards throughout the industry. Its Head of Process Engineering is a sector expert who co-authored the UK’s Best Practice Guide to power station safety.

Services

RJM offers a wide range of products to suit applications across all types of thermal plant, from ultra-low NOx burners for coal-fired utility boilers to new fuel trains for biomass and EfW plants.