Services

RJM offers a full range of services that complements its product portfolio. Typically an RJM project will consist of a tailor-made combination of products and services, brought together to meet the precise needs of each customer.

Site Survey (Combustion Audit)

This is the initial engineering stage for RJM, used to understand the current status of the plant.

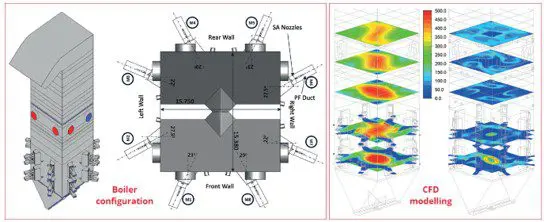

CFD Modelling

CFD modelling performed by RJM is designed to deliver accurate, robust and practical solutions that enable power plants to improve a wide range of combustion, emissions and other operational issues.

Combustion System Engineering

RJM specialises in resolving complex and challenging combustion challenges. The review, evaluation and engineering of both existing and new combustion systems is at the heart of RJM’s core competencies.

Combustion Optimisation+

A regular programme of combustion optimisation will help ensure the optimal performance and profitability of thermal power generation assets.

Fuel Assessment

Successful simulation of coal combustion relies on the accuracy of the combustion model and requires advanced coal characterisation data.

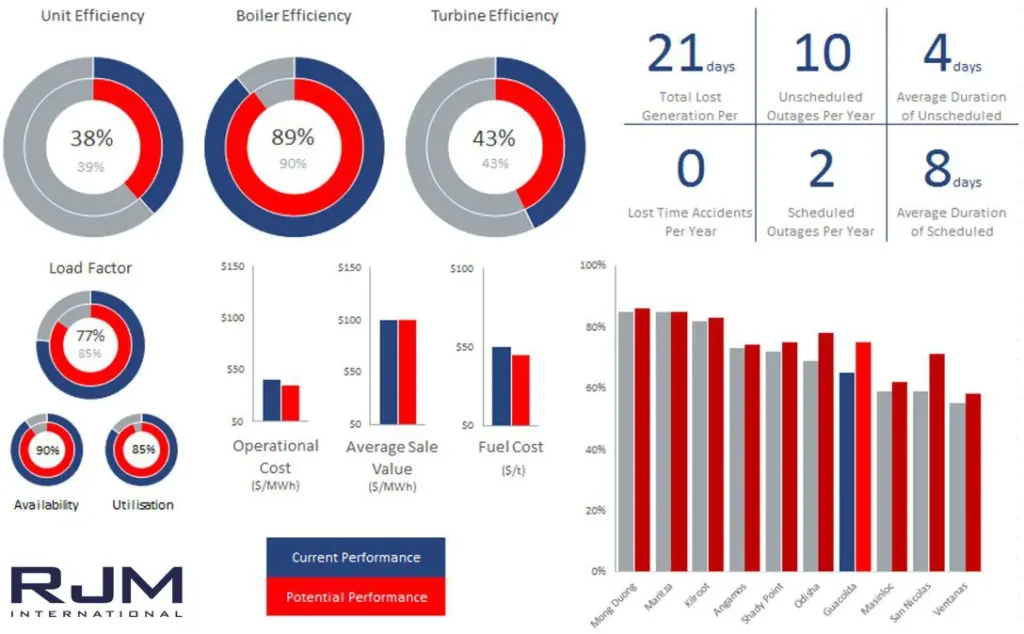

Benchmarking+

RJM has successfully completed over 60,000MWe of combustion improvement and emissions reduction projects across a wide range of fuels and firing configurations from all the leading boilermakers.

Baseline Testing

Using calibrated measuring equipment gives RJM an accurate set of data points that cover off all aspects of combustion performance.

Material Handling & Fuel Delivery

With expertise across all aspects of material handling, the RJM team can identify problem areas and deliver a solution with appropriate guarantees.

Investment Assessment

RJM can support financial decision-makers by providing specialist, technical expertise across a range of investment areas and help them determine a clear way forward that meets their investment criteria.

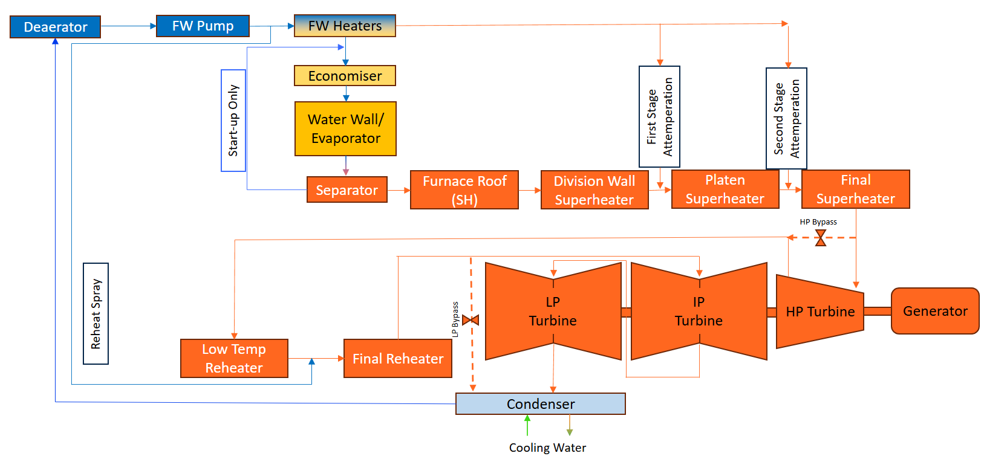

Boiler Performance Study

Poor combustion performance and flame dynamics can often lead to boiler performance issues, due to changes in the heat profile through the boiler and the rate of radiative and convective heat transfer.

Boiler Air Ingress Study & Thermal Survey

As boilers in continuous operation deteriorate over time and maintenance costs increase, it is common for many boiler systems to develop increased air ingress (air leaking into parts of the system under suction), including the boiler, backpass, airheater and flue gas ducts.

Remote Monitoring

RJM has the capability to remote monitor any plant that has a suitable interface with its DCS (Digital Control System).

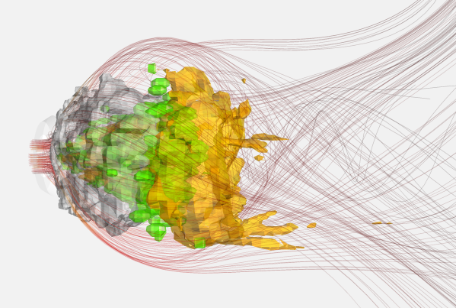

Physical Modelling

RJM uses physical modelling (often in conjunction with CFD modelling) to help identify fuel / air flow issues such as uneven distribution through the air ductwork or fuel pipes, which can result in sub-optimal fuel flow at the burner or nozzle.

Technical Services Agreements

A Technical Service Agreement (TSA) establishes an agreed relationship and gives the customer operational certainty in the medium to longer term.

Safety

RJM adheres to all national and international safety legislation and leads on improving safety standards throughout the industry. Its Head of Process Engineering is a sector expert who co-authored the UK’s Best Practice Guide to power station safety.

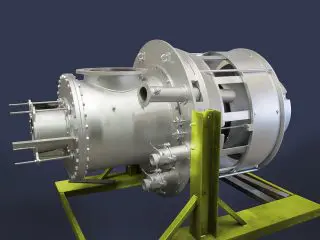

Products

RJM offers a wide range of products to suit applications across all types of thermal plant, from ultra-low NOx burners for coal-fired utility boilers to new fuel trains for biomass and EfW plants.