CFD modelling is a very important part of the RJM offer and underpins the majority of its projects.

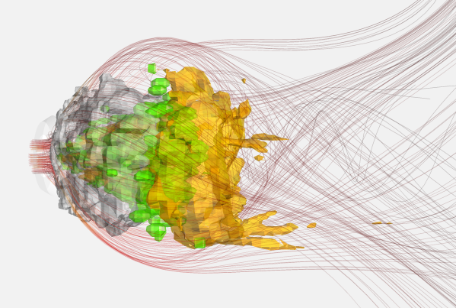

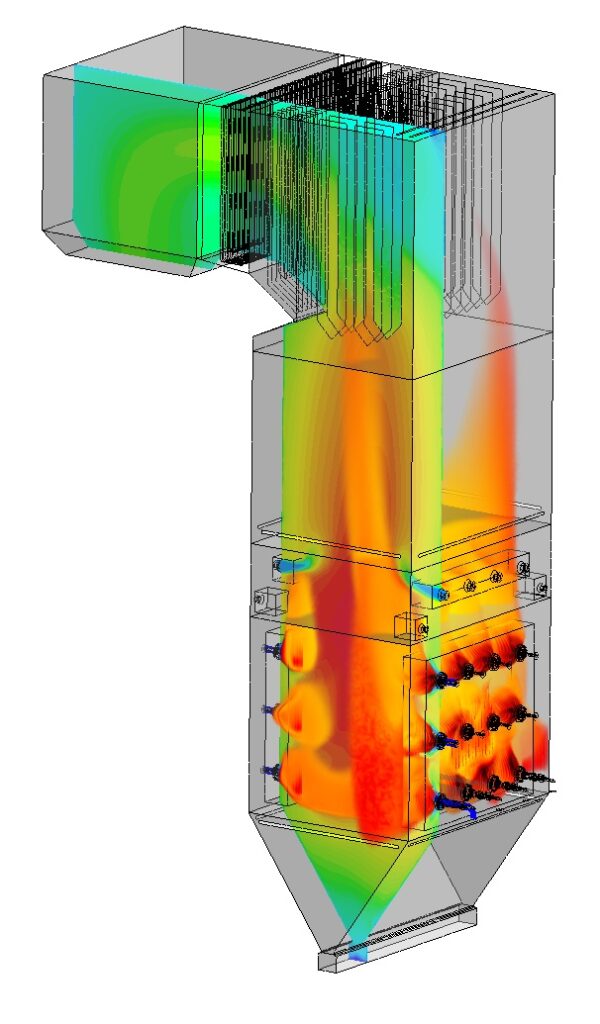

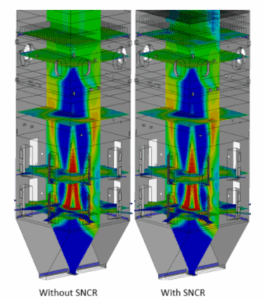

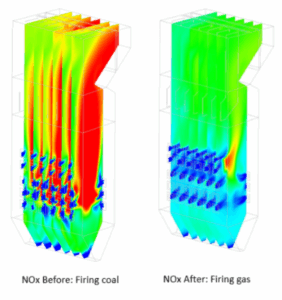

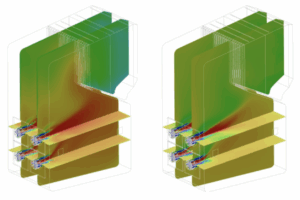

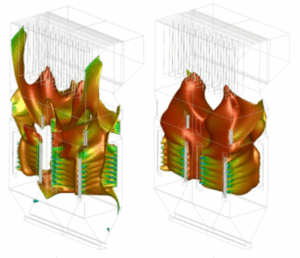

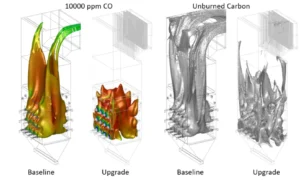

By creating a virtual model of the plant within the CFD framework it enables RJM’s engineers to gain a thorough understanding of how critical aspects of the plant are currently operating, whether that be fuel/air flow, flame profile or combustion parameters. This first stage also confirms why and where NOx, CO, SOx, dust, fouling and slagging material are being formed.

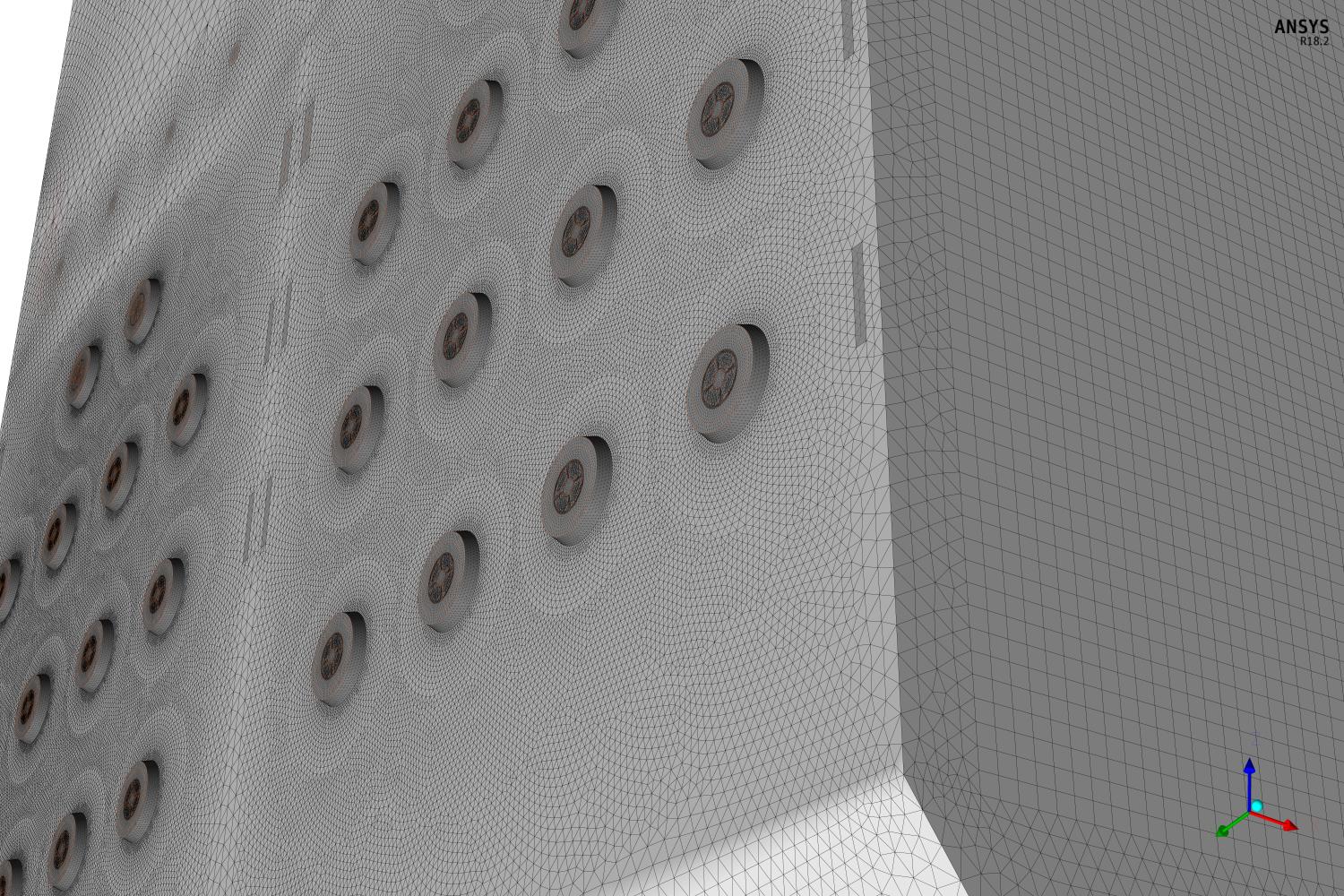

Secondly, it enables RJM’s CFD engineers to make changes to plant equipment within the virtual model. Burner configuration, nozzle size and location, fuel and air velocity, fireball location and temperatures can all be optimised as the model is “run” through a series of iterations. These incremental changes deliver step-by-step improvements each time until the objectives of the plant’s performance upgrade are met. These improvements include the reduction of NOx and CO emissions, reduced firewall corrosion, reduced slagging and better thermal efficiency.