Better reliability; meeting NOx ELV of 200mg/Nm³

Key Challenges

This new lignite-fired 345MWe plant was unable to operate stably and efficiently across the full load range and meet LCPD ELV of 200mg/Nm³ or below for new plants.

RJM Solution

RJM carried out a full furnace CFD model combined with baseline test data to understand the combustion dynamics of the boiler, plus physical modelling study of the mill and burner systems. To create strong and stable furnace circulation, RJM designed a number of nozzle inserts for various air ports, modified the injection angles and strategically-placed baffles were installed in the PF ductwork to improve and control PF distribution to the vapour burners and the main burners.

Before

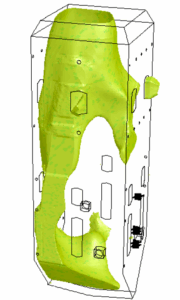

- Prior to the RJM upgrade, the fireball was off-centred and interacting with walls

- There was incorrect secondary air momentum and sub-optimal injection angles

- Resulting in high NOx, low cycle efficiency, material build-up on the grate and high carbon in ash

After

- The RJM upgrade focussed on secondary air introduction, centralising fireball

- Less than 200 mg/Nm³ NOx on all loads

- Improved cycle efficiency

- Resolved material build-up

Results

These modifications allowed the boiler to be operated at design conditions with minimal build-up of material on the grate, with compliant NOx ELV emissions of 200mg/Nm³ whilst maintaining boiler efficiency.

“This was a very critical and challenging project technically and in terms of schedule.

“The results enabled the plant to generate reliably while meeting tough emissions targets.

“We will definitely use RJM in future projects,” confirmed Peter Lithgow, CEO and Country Manager Bulgaria – AES Corporation, USA

Read the full article in PEI here: PEI May 2015 (Maritza)

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system