Coal-to-Gas Conversion, USA

The Challenge

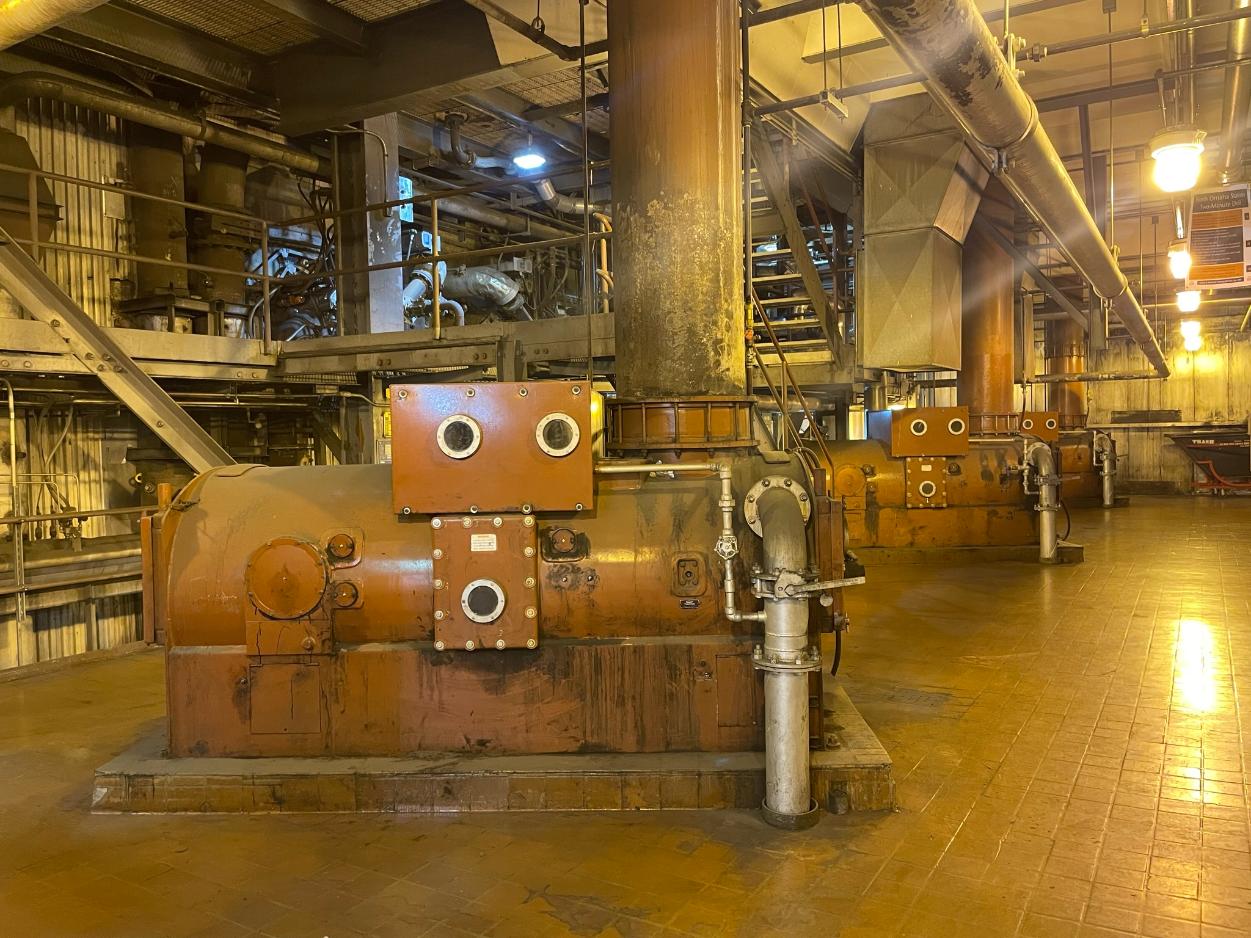

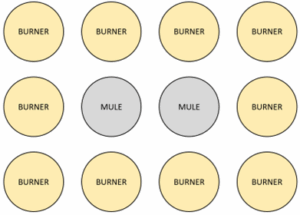

The priority for this coal-fired, 210 MWe Foster Wheeler boiler with 12 wall-fired burners in a 4 x 3 checkerboard configuration was to adopt new measures that would reduce the environmental impact of the plant on the town.

Switching from coal to gas was assessed as the optimal way to avoid environmental issues around coal transport, coal storage and coal-related emissions such as NOx, SOx and particulates, as well as extending the life of the plant. In addition, the senior management team at the plant were keen to return the plant to its design output of 230 MWe plant, as well as improve efficiency, availability, flexibility and reliability. In terms of NOx emissions, the targets were set as follows: 0.25 lb/MMBTU – 0.30 lb/MMBTU NOx with no FGR; ˂ 0.10 lb/MMBTU NOx with 25% FGR.

RJM Solution

Following a thorough review of existing operations and baseline tests, a programme of Computational Fluid Dynamic (CFD) analysis helped determine the design of the new RJM custom-engineered hardware. At the heart of the coal-to-gas upgrade were ten new Ultra-Low NOx CleanAir Burners™, with two centrally-located burner positions converted to mule units.

RJM also designed and supplied all the other new ancilliary components, retaining as many “non-performance critical” parts as possible.

Results

This project is still ongoing.

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system