Dual fuel NOx reduction programme

Key challenges

The key challenge on this dual fuel power plant was to reduce NOx on gas <200mg/Nm3 and on oil to <400 mg/Nm3 with no detrimental loss in efficiency, as well as reducing furnace vibration and high metal temperatures in the reheater.

RJM Solution

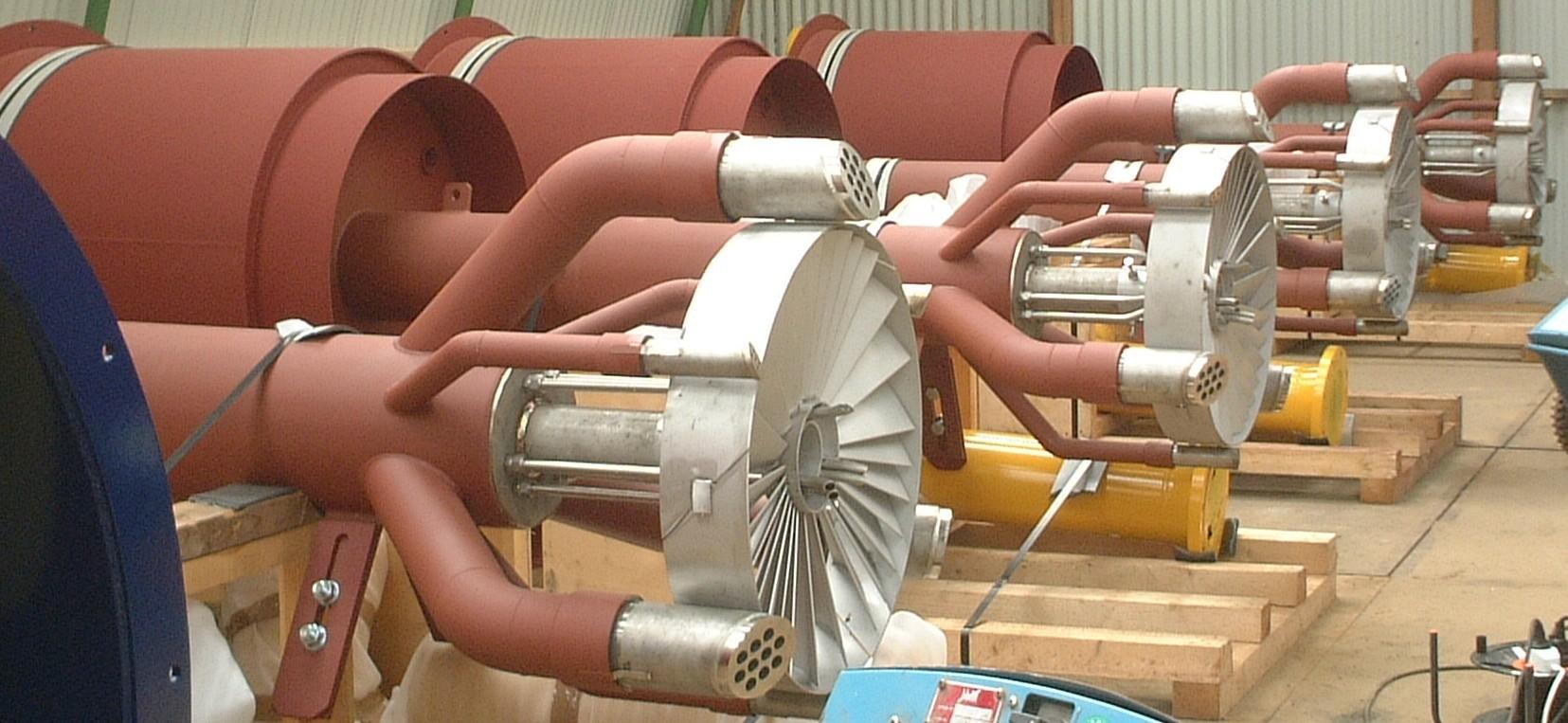

RJM modelled, engineered, and supplied 18 new Ultra-Low NOx gas burners, with start-up burner modifications, operating with increased FGR to reduce NOx emissions to below LCPD limits.

Results

RJM’s modifications reduced NOx when firing gas to 100mg/Nm3 with improved heat transfer in the furnace. The plant was also now able to operate with a stable flame, as the original burners were unstable at higher FGR rates. The problems at start-up with a cold boiler and boiler furnace vibration were also eliminated. Following commissioning and optimisation, all performance tests were fully met.

“RJM is definitely a great company to work with. The work RJM did here was also very good value for money, so we are completely satisfied.”

Jos Peeters

Senior Asset Engineer, Essent Energie, the Netherlands

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system