Full plant performance upgrade

Key Challenges

Commissioned in 2021, this 24 MWe Outotec fluidised bed gasification plant firing RDF (Refuse Derived Fuel) was experiencing various operational problems. For example, due to over-reliance on its secondary support fuel, it did not meet the criteria to qualify for the Contracts for Difference low carbon subsidy scheme, which seriously impacted on the financial viability of the plant. In addition, there were material handling issues and also an excessive amount of slag build-up in the gasifier which resulted in bed fluidisation issues and a build-up of material in the FGD (Flue Gas De-Sulphurisation) scrubber. This meant that numerous unplanned outages were needed to take the unit offline so that the build-up of material both within the gasifier and in the FGD unit could be manually removed.

RJM Solution

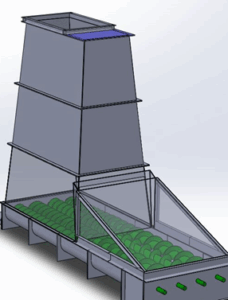

To investigate unstable combustion, RJM used DEM (Discrete Element Method) modelling to track fuel particle behaviour dynamically, which confirmed that the fuel feed system was sub-optimal. This was remedied with a total redesign of the fuel train, including a new screw feeder.

Video shows smooth draw-down of waste material following RJM modifications to the fuel delivery systems

RJM also undertook a full system review of the gasifier using Computational Fluid Dynamic (CFD) modelling to understand how the Over-Fire Air (OFA) nozzles were impacting on gasification and syngas combustion.

With 88 nozzles on the 1st level, 128 on the 2nd level and 160 on the 3rd, RJM designed an innovative solution which redistributed airflow through each nozzle to promote more uniform mixing in the gasifier.

In addition, a new Over-Fire Flue Gas Recirculation (0FGR) system was designed, constructed and connected to each OFA level. This provided an environment where flue gas is rapidly mixed with air to dilute combustion air and reduce peak and bulk flame temperatures. By reducing these temperatures, RJM was able to reduce the formation of slag on the gasifier walls.

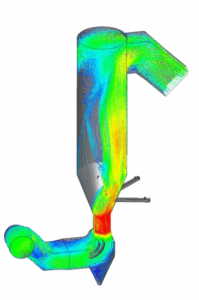

RJM then used CFD to model the flow regime through the FGD scrubber to understand why solid material was dropping out of the scrubber and building up within the boot. It resulted in another innovative solution being developed where the flow regime was stabilised through the scrubber, significantly reducing the material build-up within the scrubber boot.

After testing and optimisation of this series of re-configurations to plant equipment, new control philosophies were then introduced.

Results

Following this major upgrade programme, of which the investment in the new oFGR system was the most costly, the plant was able to run longer campaigns more consistently and export more power to the grid. RJM’s modifications also enabled the plant to maintain a constant flame across the MWe output range and ensured that the plant qualified for the CfD scheme.

Internal view of the new oFGR ducting being installed

CFD analysis of the Flue Gas Desulphurisation unit at Hull

CAD image of the RJM design for the new fuel train and feeder unit

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system