Gas Burner Upgrade Project

Background

Associated British Foods plc has set itself the goal to achieve net zero greenhouse gas emissions by 2050.

To meet this goal, Azucarera, its sugar subsidiary in Spain, has embarked on a programme to reduce its environmental impact through a variety of initiatives, including reducing emissions, waste and resource use at its three sugar beet processing plants, a logistics & packaging plant and an R & D Centre, working with its EPC contractor, ICORSA.

Key challenge

To facilitate the plant performance upgrade at the three sugar processing plants, ICORSA selected RJM to design and manufacture a new natural gas burner firing system that would significantly reduce emissions of NOx and CO and provide added versatility in terms of fuel options.

RJM Solution

RJM developed an innovative burner solution which optimised performance when firing gas, but also retained the Heavy Fuel Oil-firing capability as a back-up fuel. RJM also designed the burners to include a biogas-firing capability and – planning further ahead – hydrogen. The biogas comes to the burners via a separate process on the plant and so it requires its own set of dedicated pokers, whilst the hydrogen is blended into the natural gas stream at around 15% by volume.

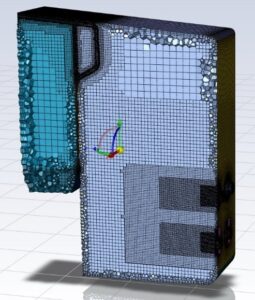

In order to arrive at an optimal design for this multi-fuel burner, RJM carried out two sets of CFD (Computational Fluid Dynamic) analysis.

Firstly, to determine the correct combustion air flow to the burners, a Single Burner Air Distribution Study was undertaken. By analysing every aspect of air flow in the combustion air ductwork, including the Forced Draft (FD) fan outlet; the windbox inlet; the windbox itself and the burner register, RJM was able to determine the size and location of any air splitters that would be needed to achieve optimal air distribution to and within each burner.

The second CFD study focused on Combustion Analysis to determine the correct architecture of the new RJM burners, including the number, type and positioning of the gas pokers that would be needed. This CFD study analysed a number of different firing scenarios to determine optimal combustion. To achieve the lowest possible emission levels, RJM proposed including an induced Flue Gas Recirculation (iFGR) system, involving ducting from before the stack, back to the forced draft fan, to allow a pre-calculated flow of flue gas to be mixed with the combustion air. This technology is used to reduce peak temperatures and therefore the formation of NOx.

Above: CFD geometry of the the original boiler drawings

Above: Computational grid of the boiler using 5.8 million poly-hexacore cells

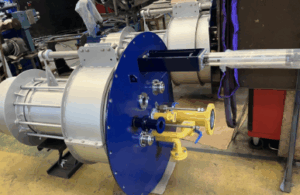

Above: Close-up of new RJM burner for Miranda

Above: Four burner installation at Miranda

Results

Having completed the CFD work, RJM was then able to design the new burners to suit the specific requirements of the plant. They were commissioned in 2024 and the customer was happy with their performance. All the emission guarantees were fulfilled, with NOx reduced to 74mg/Nm³ and CO reduced to 5mg/Nm³.

Read the article in Power Engineering International (published on 5th August 2025) about RJM’s upgrade of the Azucarera sugar processing plant at La Bañeza:

https://www.enlit.world/library

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system