Major NOx and dust reduction project

Key challenges

As part of Kosovo’s accession planning to join the European Union, its 680 MWe lignite-fired power station Kosovo B, needs to be brought up the latest EU standards. This means that NOx emissions must be significantly reduced, from around 700-800 mg/Nm3 to less than 200 mg/Nm3 at 6% O2 with SNCR, and dust emissions down from 300-700 mg/Nm3 to 20 mg/Nm3. Overall plant efficiency must also be increased to recover full load of 339 MWe per boiler, up from around 292 MWe.

RJM Solution

Using its tried and tested approach, RJM surveyed in great detail every aspect of the plant and conducted numerous CFD-based fuel / air flow and combustion modelling assignments to arrive at a solution that has at its heart, RJM-designed and manufactured ultra-low NOx burner components as well as a range of other upgrades. Other consortium members on this € multi-million project are responsible for the engineering and the dust reduction measures.

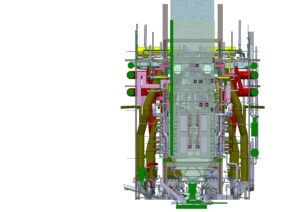

Model created from a laser scan for clash detection purposes, to ensure new RJM burner hardware and FGR ducting can be successfully incorporated into the plant

Results

Implementation progress on this project was delayed by the Covid-19 pandemic of 2020 / 2021 and by the fact that a programme of works to address boiler dilatation had to be completed before the de-NOx and dust reduction elements of the upgrade could take place.

This dilation work has now been completed and following further negotiations with the EU Contracting Authority, RJM, together with its consortium partners, Engineering Dobersek and Wallstein Rothemühle are now back on track to deliver the project during 2025 / 2026.

Drone footage https://www.youtube.com/watch?v=sAWe_kVEPBk

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system