NOx abatement strategy

Key challenges

This rotary kiln firing system processes a range of hazardous and medical waste streams and the plant operator initially tasked RJM to carry out a NOx abatement study.

RJM Solution

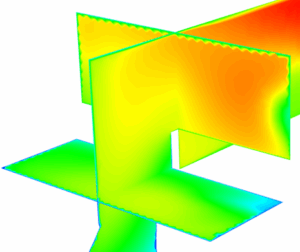

RJM carried out a site survey and a cost-benefit analysis for the available options for improved NOx control. Due to the unusual configuration of this plant, a CFD study was carried out to ensure that the proposed SNCR system would be installed in the optimum location to meet the performance requirements.

RJM used CFD to plot the temperature range to identify the optimal range for successful urea injection

Results

The findings from these various tests and modelling suggested that an SNCR system, injecting the correct type and amount of reagent into the secondary chamber, may be the most appropriate way forward to control NOx. RJM is now continuing to work with the customer to deliver the optimal solution.

Recognising RJM’s effective and results-driven approach, Tradebe has appointed RJM to carry out a range of other operational improvements at its sister site in Wrexham.

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system