Resolving high CO and reagent usage

Key Challenges

RJM was hired to assess and correct the high levels of CO at the stack and also tasked with exploring why the plant, which fired woody biomass, was utilising very high levels of costly SNCR reagent.

RJM Solution

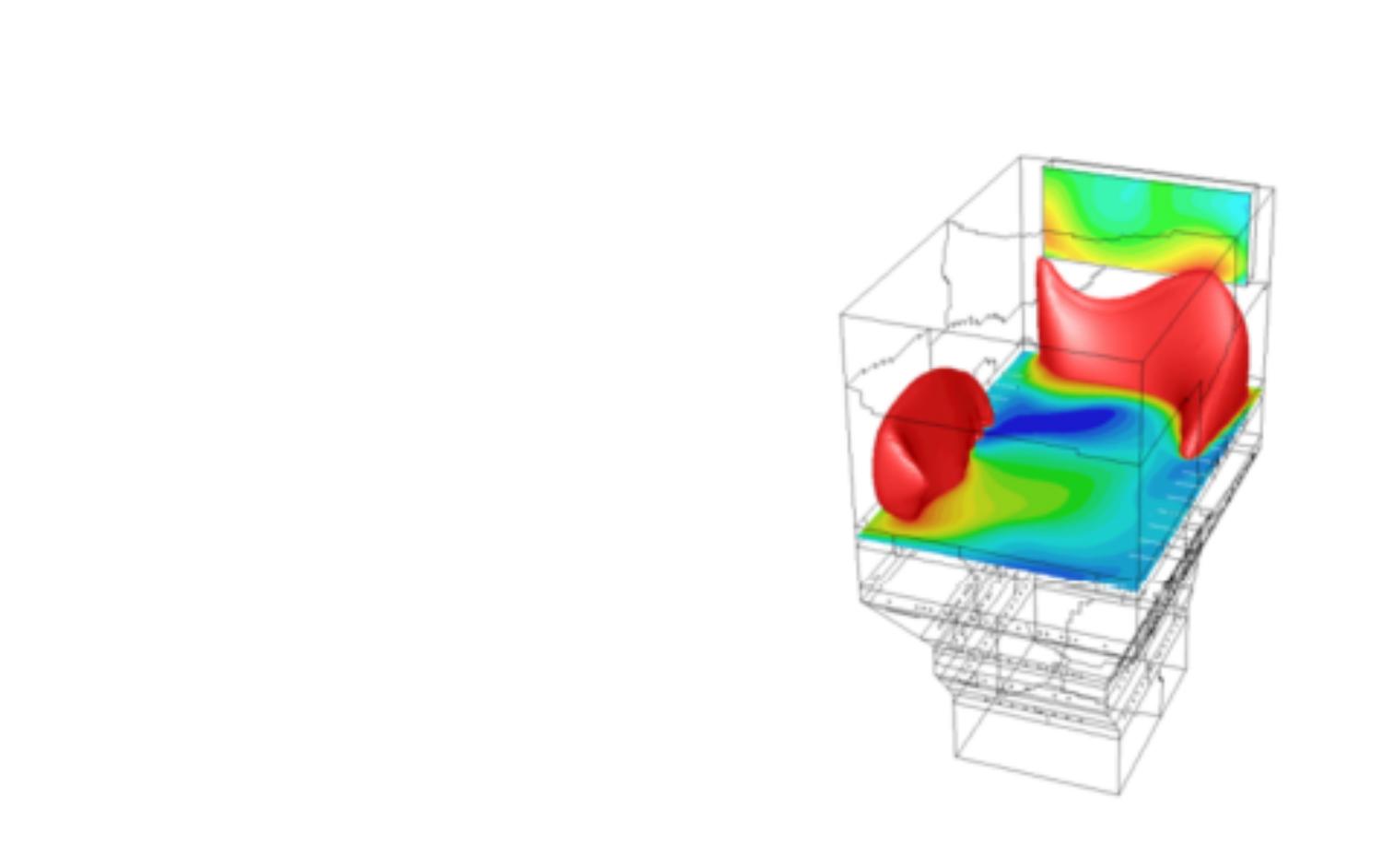

Initially, RJM carried out a Combustion Audit and a CFD modelling exercise at this Bubbling Fluidised Bed (BFB) firing woody biomass. It showed a lack of mixing between the existing OFA injectors and the produced CO. RJM’s solution was to induce rotation into the furnace, which promotes CO oxidation. The design was optimised with CFD, implemented and proved successful, with CO levels coming down to below permit levels. This was the first ever implementation of this innovation. RJM’s competitors have since copied this successful design modification. The plant’s operators now have the information they need to return the unit to optimal performance.

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system