Site survey, single burner CFD study and burner modifications

Key challenges

To resolve various combustion issues and improve plant performance.

RJM Solution

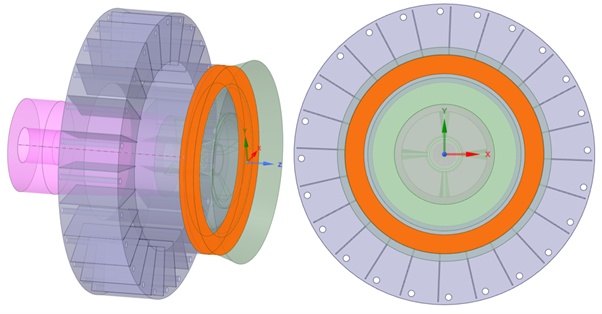

Following a site survey, RJM then carried out a programme of CFD modelling to measure burner airflow. This included a programme of single burner and windbox iso-thermal modelling, plus combustion modelling of the existing burners. It was planned that this information would enable the existing burners to be optimised as a temporary solution, prior to baseline testing, full furnace and upgrade CFD modelling being carried out. The ultimate aim was to carry out a full set of burner and OFA modifications during the next outage.

Results

The modelling work carried out by RJM confirmed that once the programme of designed and engineered modifications had been completed, the plant would be operating more reliably and more efficiently. Eren Enerji, the plant owner, went ahead with RJM’s proposals and the major plant performance upgrade project was carried out during 2024.

See follow-on summary of the work, “New Coal Burner Upgrade Project – Coal”.

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system