Ultra-Low NOx Burner upgrade to meet IED compliance

Key challenges

This 1970s era plant had opted out of the LCPD and was set to close. In order to remain operational beyond 2016, the plant was required to re-register as a new plant and meet the more stringent IED emissions standards applicable to new plants.

RJM Solution

The Ultra-Low NOx conversion designed and engineered by RJM to achieve the required emissions limits, included 12 twelve brand new RJM Ultra-Low NOx gas burners, an Induced Flue Gas Recirculation system and an iFGR Water Spray Cooling System for ensuring maximum generation capacity with compliant emissions.

RJM’s proprietary water spray system designed to ensure maximum generation capacity with compliant emissions

Some of the new RJM burners destined for Ballylumford

Results

All IED Emission Limit Values were satisfied. NOx was reduced to <100mg/Nm³, CO was reduced to <10mg/Nm³ and particulate matter was reduced to <3mg/Nm³. Thanks to the unique RJM-designed iFGR Water Spray Cooling System, the unit capacity was reduced by only 10MWe (6%) – significantly less than the 25 MWe (15%) reduction estimated by the owners.

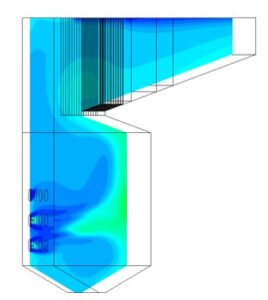

RJM’s CFD analysis successfully predicted that NOx levels wuuld be extremely low when firing with 40% FGR

NOx reduction project to meet Phase 1 RACT regulations

Engineer, model and supply new NOx reduction system