Selecting the right biomass fuel, determining the most appropriate fuel handling, fuel storage and fuel milling requirements are all within RJM’s scope.

In addition, modelling how co-firing will change combustion performance in terms of flame profile and temperature, as well as resolving new fuel-related challenges around corrosion, erosion, fouling, slagging and emissions are all important areas which need to be fully addressed if the conversion is to be a success.

Several of RJM’s engineers have played key roles in converting utility-scale power plants from coal to biomass, including in the UK, Lynemouth and the four unit, 1,428 MWe Tilbury B, one of the world’s first conversions of a utility power station from coal to 100% biomass firing.

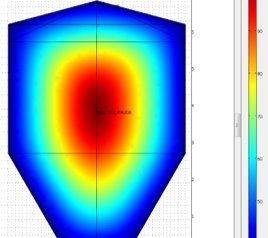

Image shows finite element analysis for biomass silo self-heating